The sandwich cake and two -layer cake are very popular because of

its light and tasty and are enjoyed as a treat anywhere during the

day or evening.

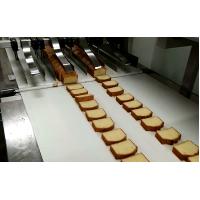

The layer cake are baked in the steel sheet belt and sandwiched

together with one layer fillings, and finished with coating and

toppings.

The mixed batter are manifold on the steel sheet and bake into

tunnel oven, after baking, the cake sheet are split into linear

cakes, half of them are lift up, the others are turned over and

pasted cream, then the top linear cake put on the bottom layer, the

layered linear cake are cut into individually sized portions then

transport to packaging machine.

In addition to the drying oven, the line is suitable for producing

cake rusk.

Producing perfectly layers cake relies on the accurate depositors

and gentle sponge handling, combined with optimized automation to

increase throughput, and minimize waste.

The line can be equipped with:

Aeration Mixing Machine

Aeration mixer for decorator (Optional)

Greasing Unit

Batter maniflod depositor

Grip decorate device

Tunnel Oven

Inclined cooling conveyor

Transversal roller cutter

Layering units

Folding unit

Cream extruder

Cream aeration system

Make-up conveyor

Ultrasonic cutter

Cooling Belt Conveyor with UV tunnel

Packaging machines

Specification of equipment :

Oil Spraking unit/ paper machine

Working width: 1M

Batter depositing manifold(sheeting)

Workding width: 1M

Sheeting thickness is adjustable: from 0.6 – 1.2mm

Decoration & Lidding Machinery

Working width: 1M

Tunnel oven

1.The oven is constructed gas-tight baking tunnel, divided into 2m/

section with gas-tight connection between sections, each section is

connected with a frame.

2.The baking tunnels are insulated with high-quality insulation

material, in order to reduce heat loss to a minimum.

3. View ports that can be opened are fitted at the oven sides for

every zone.

4. The operating panel is fitted near the oven out feed. Operation

can be from either right or left hand side.

5. The temperature is controlled in each baking zone independently,

for both upper and bottom flames. Each temperature reading be

measured and displayed on touch screen and temperature controller.

6. Production transportation way: BY steel belt

7.An OMRON PLC system is used for the oven production control.

Cooling conveyor

A: it is stainless steel mesh belt with Alcohol Spraying Device

B: Bottom Cooling conveyor is made by PU belt ---food level

C: Bridge cooling conveyor

Half cake stripe to go through there, half stripe to run on the

underneath bottom conveyor to leave the space to turn the cake face

down and overlap to another stripe.

Driven cutting knives

1 set of driven cutting knives to cut strips of cake: executed with

9 and 25 knives(The number is changeable depend on the cake size)

for cake products, working width 1000mm.

Two layer cake layering unit

Two layer cake layering unit, to supply strips of cake & place them

on top of cake strips underneath.

Pressing roller

The height of product passing under can range from 0-50mm.

Mechanical guillotineMechanical guillotine provided with a knife to cut the products at

length, the no. of strokes is adjustable up to 55 strokes per

minutes; maximum cutting height 60mm; cutting length adjustable by

means of servo motor.

Product conveyors

1800curve conveyor

Transfer swiss roll and layer cake from make up line conveyor to

cooling conveyor, Executed with its own AC frequency controlled

speed drive.

Cooling conveyor with 6meters UV shade

Working width1200mm,length 15m, with 6Meters UV shade, Executed

with its own AC frequency controlled speed drive in connection with

packaging line.

FAQ:

Q1: Are you a factory or trading company?

A1: We are a factory. GuangDong SaiMai Industrial Equipment co.,LTD

is located in GuangDong Province, China.

Q2: Can I customize the produces' size?

A2: Yes, We provide professionally customize to meet the needs of

your company

Q3: How does your factory control the quality?

A3:Our Aims: Maintain High Quality, Keep Improving, Provide the

Best Service, Be Client-Oriented

Our Goal: To be the top bakery equipment manufacturer in the world

OUR WORKSHOP

PACKING & DELIVERY